Wire Rope

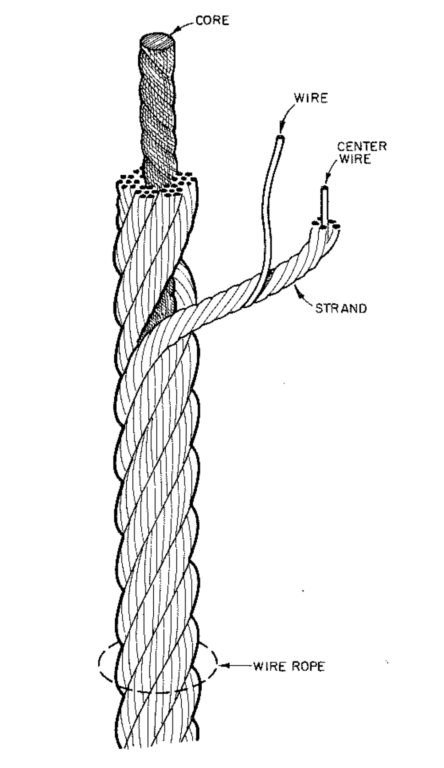

In and of itself, wire rope is a machine consisting of three basic components; while few in number, these vary in both complexity and configuration so as to produce ropes for specific purposes or characteristics. The three basic components of a standard wire rope design are: 1) wires that form the strand, 2) multi-wire strands laid helically around a core, and 3) the core.

Wire, for rope, is made in several materials and types. By far the most widely used material is high-carbon steel. This is available in a variety of grades each of which has properties related to the basic curve for steel wire rope. Wire rope manufacturers select the wire type that is most appropriate for requirements of the finished product.

Steel wire strengths are appropriate to the particular grade of the wire rope in which they are used. Grades of wire ropes are referred to as plow steel (PS), improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS).The plow steel strength curve forms the basis for calculating the strength of all steel wire rope wires; the tensile strength (psi) of any steel wire grade is not constant – it varies with the diameter and is highest in the smallest wires.

The most common finish for steel wire is “bright” or uncoated. Steel wires may also be galvanized, i.e., zinc coated. “Drawn galvanized” wire has the same strength as bright wire, but wire “galvanized at finished size” is usually 10% lower in strength.

Strands are made up of two or more wires, laid in any one of many specific geometric arrangements, or in a combination of steel wires with some other materials such as natural or synthetic fibers.

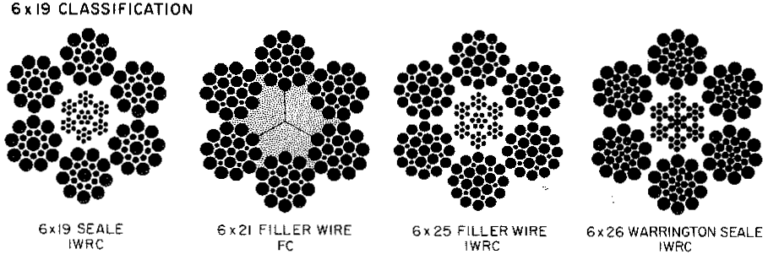

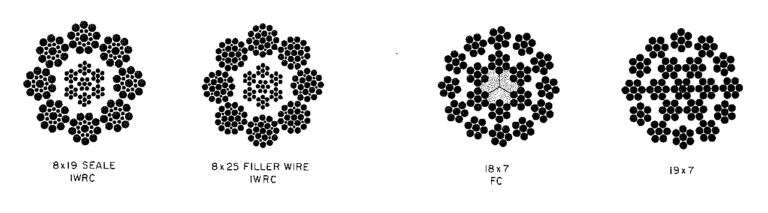

The core is the foundation of wire rope; it is made of materials that will provide proper support for the strands under normal bending and loading conditions. Core materials include fibers (hard vegetable or synthetic) or steel. A steel core consists either of a strand or an independent wire rope. The three most commonly used core designations are: fiber core (FC), independent wire rope core (IWRC), and wire strand core (WSC). Catalog descriptions of the various available ropes always include these abbreviations to identify the core type. Courtesy of Wire Rope Users Manual & American Iron and Steel Institute